Information

Plastic Injection Molding 101

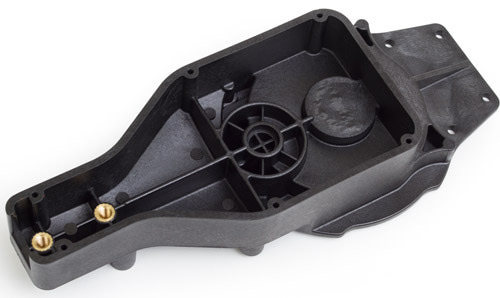

Injection molding is a manufacturing process for producing plastic injection molds from thermoplastic and thermosetting plastic materials. Material is fed into a heated barrel, mixed, and forced into a mold cavity by a reciprocating screw or a ram injector, where the injection molded part cools and hardens to the configuration of the mold cavity. Molds are manufactured to the specifications of a part design and assigned to a mold or tool maker. Injection molds are usually constructed of steel or aluminum and precision-machined to form the features of the desired parts. Injection molding is widely used for manufacturing a variety of parts, from the smallest component to large automobile panels.

Injection molding is a manufacturing process for producing plastic injection molds from thermoplastic and thermosetting plastic materials. Material is fed into a heated barrel, mixed, and forced into a mold cavity by a reciprocating screw or a ram injector, where the injection molded part cools and hardens to the configuration of the mold cavity. Molds are manufactured to the specifications of a part design and assigned to a mold or tool maker. Injection molds are usually constructed of steel or aluminum and precision-machined to form the features of the desired parts. Injection molding is widely used for manufacturing a variety of parts, from the smallest component to large automobile panels.

Injection Mold Production Process

With injection molding, small plastic pieces are gravity fed from a hopper into a heated barrel. As the granules are slowly moved forward by a screw-type plunger, the plastic is forced into a heated chamber called the barrel, where it is melted. As the plunger advances, the melted plastic is forced through a nozzle that seats against the mold sprue bushing, allowing it to enter the mold cavity through a gate and runner system. The injection molded part remains at a set temperature so the plastic can solidify almost as soon as the mold is filled.

Plastic Injection Mold History

In 1868, John Wesley Hyatt invented a way to make billiard balls by injecting celluloid into a mould. Hyatt improved the celluloid so that it could be processed into a finished form. In 1872 John and his brother Isaiah patented the first injection molding machine. The simple machine contained a basic plunger to inject the plastic into a mold through a heated cylinder. The industry progressed slowly over the years producing injection molded products such as plastic buttons and hair combs. In the 1940's the injection mold concept grew in popularity as a result of World War II creating a huge demand for high-volume, low-cost products.

In 1946, James Hendry built the first screw injection molding machine, revolutionizing the plastics industry with an auger design to replace Hyatt's plunger. The auger was placed inside the cylinder to mix the molded material before pushing it forward into the mold. The advancement allowed different plastic material types, such as colored plastic or recycled plastic, to be mixed with the virgin material before being injected.

Today screw injection molding machines account for 95 percent of machines in the industry. Clearly, plastic injection molding capabilities has evolved over the years. Plastic Parts, Inc. is proud to be a contributor to the continuous advancement of this growing industry.