Our Capabilities

Our Capabilities

From Concept to Completion

At Plastic Parts, Inc., we provide turnkey solutions to support every stage of plastic part development and production, from early design to final delivery. With nearly 60 years of experience in precision manufacturing, we recommend and implement efficient, high-quality solutions tailored to each project. We take pride in helping customers achieve better outcomes, reduce risk, avoid costly missteps, and deliver products that meet exacting standards for performance, durability, and value.

Core Capabilities

These capabilities form the foundation of our customer relationships and set the stage for successful manufacturing.

Design Consultation

Great outcomes begin with smart, manufacturable design. Through Early Supplier Involvement (ESI), we collaborate early to refine part specifications, assess materials, and improve manufacturability. This process reduces costly revisions and helps accelerate time to market.

We utilize advanced tools, including CAD, mold flow analysis, and CAM software, to simulate performance and ensure that each part is ready for tooling and production. Our team also supports tool sourcing and production planning to facilitate a seamless transition of designs into manufacturing.

We leverage our decades of hands-on experience and deep knowledge of the injection molding process to guide material choices. From recommending thermoplastics and additives, each decision is based on meeting engineering and aesthetic needs based on thermal, mechanical, and regulatory requirements.

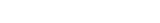

Prototyping

Prototyping bridges the gap between ideation and production. We offer CNC-machined soft tooling and additive manufacturing (3D printing) technologies, including FDM, SLA, and SLS, to produce functional prototypes for form, fit, and performance testing.

Our prototype molds help validate part and process performance using production materials. This process reduces development risk and supports quicker, more informed decision-making.

Custom Injection Molding

Plastic Parts, Inc. specializes in custom injection molding for medical, transportation, consumer, and industrial applications. Our ISO-certified process, in-house tooling, and advanced molding techniques ensure repeatable quality from first shot to high-volume runs.

Our capabilities include:

- Scientific molding for process control and defect reduction

- Insert molding for stronger, multi-material parts without secondary fasteners

- Overmolding for improved grip, ergonomics, or impact resistance

- Gas-assist molding to reduce material use and warping

- Plated plastic parts for a metal-like appearance without added weight

Comprehensive Production Capabilities

As a full-service manufacturer, Plastic Parts, Inc. offers more than design and molding. Our turnkey manufacturing capabilities support part preparation, finishing, integration, and packaging so that each component is delivered ready for end-use.

Value-Added Manufacturing Capabilities

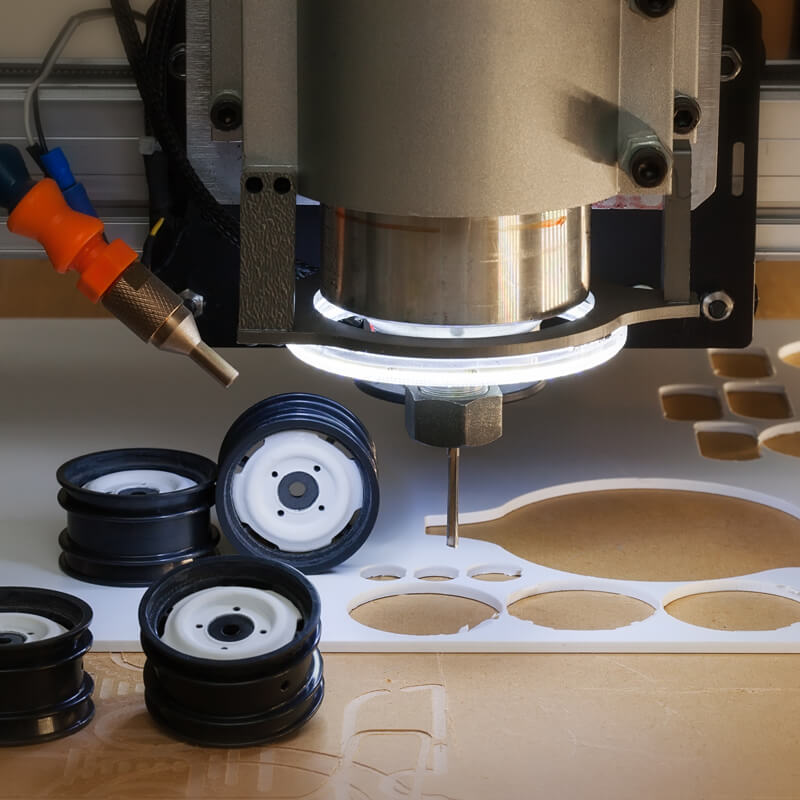

Machining

We provide precision turning, drilling, milling, and cutting tailored for plastic materials. Our team maintains tight tolerances and accounts for the unique thermal and mechanical properties of plastic.

Welding

We offer a range of plastic welding methods — including ultrasonic, spin, and vibration welding. These joining techniques create durable, high-strength bonds without the need for adhesives or fasteners.

Assembly

We build and integrate components using custom fixtures, dedicated assembly cells, and automation. Our lean manufacturing process reduces labor and material handling while supporting high-quality, scalable output.

Robotic Part Picking & Packaging

Our robotic systems enhance efficiency through automated part picking and packaging. This capability supports high-throughput, consistent output, and enables just-in-time delivery requirements.

Plastic Decorating

We offer several in-mold and post-mold decorating options to enhance product appearance, branding, and durability. These techniques deliver vivid graphics, long-lasting finishes, and consistent results across all production volumes.

Our capabilities include:

- Pad printing

- UV printing

- Laser marking

- Hot stamping

- In-mold labeling (IML)

- Molded-in color

- Plating

- Protective Coating

Proven Plastic Manufacturing Expertise

What sets Plastic Parts, Inc. apart is not just what we do — it’s how we apply it.

Case in Point: A customer required lettering on a low-volume part and was considering two-shot molding. But the tooling costs were high, the risk of quality issues was significant, and pad printing wasn’t a viable alternative due to material and registration concerns. Our team recommended laser marking — a simple, cost-effective solution that produces clean, durable results tailored to the material and volume. The customer avoided unnecessary cost and risk while achieving a better product.

We bring decades of experience to every project and use our deep understanding of each process to guide clients toward the most efficient, effective, and scalable solutions.

Let’s Mold Something Great Together

Looking for a trusted partner to support your plastic part production? Fill out the form below to connect with us.

Fill out the form below to discuss your project, request a quote, or get expert guidance from our team. We’ll be in touch soon!