The Hidden Cost of Overseas IP Theft: Why U.S. Businesses Are Reshoring with Plastic Parts, Inc.

For decades, many companies have outsourced their plastic injection molding to overseas manufacturers in search of lower costs. However, the tide is turning as businesses face the harsh realities of intellectual property (IP) theft, quality control issues, and growing tariffs—especially when working with manufacturers in countries like China.

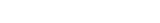

At Plastic Parts, Inc., we’ve seen firsthand how companies that offshored production struggled with counterfeit versions of their own products appearing on the market. These weren’t just unauthorized replicas—they were exact copies, right down to the packaging. Fighting these violations can be an expensive and time-consuming battle, often at the expense of a company’s profitability and reputation.

But There Is a Better Way

U.S.-based manufacturing provides greater security, higher quality control, and reliable supply chains—without the hidden risks of offshoring. More and more businesses are reshoring to trusted domestic partners like Plastic Parts, Inc., ensuring their products remain safe, competitive, and protected.

How Plastic Parts, Inc. Protects Your IP

Offshoring your manufacturing doesn’t just mean giving up control over production—it often means losing control over your own designs. Once your molds and proprietary technology leave the U.S., they can be copied, sold, and exploited—sometimes by the very suppliers you trusted.

The problem is massive. IP theft costs U.S. businesses between $225 billion and $600 billion every year, according to the Commission on the Theft of American Intellectual Property.

One industry hit especially hard is the automotive industry. Investigations have uncovered counterfeit brake pads, airbags, and fuel pumps flooding the market—many of them indistinguishable from real products, even down to the safety certifications. These knockoffs don’t just undercut legitimate businesses; they put lives at risk.

For businesses that have already suffered from counterfeits, reshoring has been a game-changer. By moving manufacturing back to the U.S., companies regain control over their products, protect their brand, and eliminate the hidden costs of IP theft.

At Plastic Parts, Inc., we make security a priority:

✔️ Your molds and designs remain exclusively yours.

✔️ We never share proprietary technology with third-party suppliers.

✔️ Less worry about unauthorized knockoffs appearing on Amazon or eBay.

Why More Businesses Are Reshoring with Plastic Parts, Inc.

Many companies that once turned to overseas production are now bringing their injection molding needs back to the U.S.—and they’re choosing Plastic Parts, Inc. Here’s why:

1. Nearly 60 Years of Trusted Expertise

Since 1966, Plastic Parts, Inc. has built a reputation as a trusted, ethical manufacturer in the healthcare, automotive, lawn and garden, power sports, and flow control industries. Our long-standing customer relationships prove that companies value a partner who prioritizes both quality and security.

2. Superior Quality and Compliance

In industries like medical devices, automotive, and power sports, even the smallest flaw can lead to big consequences. Offshore manufacturers often have inconsistent quality control, but our U.S.-based facility ensures that every part meets stringent regulatory and industry standards.

3. Supply Chain Stability

The past few years have exposed the fragility of overseas supply chains. Shipping delays, tariff increases, and geopolitical tensions make offshore manufacturing a growing liability. By partnering with Plastic Parts, Inc., you gain a reliable domestic supply chain that keeps your production on schedule.

4. Competitive, Transparent Pricing

Many companies assume that U.S. manufacturing is too expensive—but they fail to account for the hidden costs of offshoring, such as:

- Tariffs and import fees

- Shipping delays and increased freight costs

- IP theft and revenue loss from counterfeits

- Quality issues leading to product failures and recalls

At Plastic Parts, Inc., we offer competitive pricing without compromising on quality, security, or ethics.

The Cost of Inaction

For companies still outsourcing their plastic injection molding overseas, the risks are only increasing. IP theft is becoming more sophisticated, and counterfeiters are getting better at making their products indistinguishable from the real thing. Every day that passes is another day your business could be losing revenue to knockoffs—and potentially putting your customers at risk.

It’s time to rethink where and how your products are made. Plastic Parts, Inc. is ready to help your business transition to a safer, more secure, and more reliable manufacturing solution—right here in the USA.